What appears to be a children’s slide attached to the right end of the building (above) is actually the off-loading ramp for the 1,500-pound cotton bales. Weighed and stamped on the covered wooden platform, these large bales (right) must have been quite a load to muscle around in the days before fork lifts.

Looking as if it has stood for ages on the grounds of the Mississippi Agricultural and Forestry Museum in Jackson is a recreation of a 1920s-era cotton gin. This building was constructed in 1982 to house the restored equipment of the original Bisland Cotton Gin, once located at Cannonsburg near Natchez, Mississippi.

Now, the word “gin” is an abbreviation for engine, or device — as this form of the word was used at the time of the cotton gin’s invention in 1793. You may not know this but there is some controversy over who invented the cotton gin. Our history books tell us that it was Eli Whitney, yet it is possible that Whitney merely filed the patent claim for his landlady, Catherine Littlefield Greene, as women weren’t eligible to receive patents at that time. Other sources claim that she took Whitney's original flawed design and improved on it. (She was the widow, by the way, of the American Revolutionary War general Nathanael Greene.)

Eli Whitney from an 1822 painting by Samuel F. B. Morse (that's right, the guy who coinvented Morse code!).

Courtesy of the Yale University Art Gallery, Yale University, New Haven, Connecticut.

The equipment in this building was first used in 1892, and cleaned the seeds and trash from cotton for 62 years until the mill’s closure in 1954. Running three ginning machines or stands, the Bisland Cotton Gin would operate literally around the clock during the peak season, vying with three other cotton gins to process the cotton harvest in that area.

Although it only had one cylinder and an output of 55 horsepower, the large diesel engine (right) generated sufficient power to operate all of the air blowers and other equipment in the building.

The gin must have been a noisy and dusty place to work. Scores of wagons would bring what was known as seed cotton (uncleaned, just-picked cotton) from the fields to where it would be vacuumed up by a cotton suck pipe or “telescope” into a storage house or directly into the stands. Pressurized air would then force the seed cotton onto a conveyor belt where it would be fed into hoppers above the stands. There it was regulated into the works, where spinning saws would pull the lint or cotton strands through closely-spaced ribs, placed too close together to allow seeds and large pieces of debris through.

The doorway shown at left leads into the main room where the gin stands are located (below right).

The seeds would then be blown into the seed house, a separate structure set on a tower with enough clearance for a wagon to drive underneath and take on a load. The cleaned lint would be blown into a battery compressor to be transformed into a smooth continuous batting of cotton. A hydraulic ram compressed 1,200 to 1,550 pounds of this batting into the familiar bales of cotton.

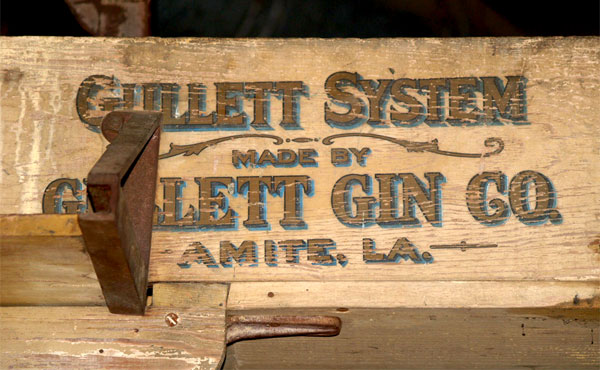

Although building for a major industry, the Gullett Gin Company still engineered a certain amount of artistic quality into their equipment. Witness the decoratively stamped endplate on one of the gin stands (below left). Even the signage on the wooden conveyor covers (below right) bears proud testimony to the care with which this equipment was finished.

This large wrench (above) no doubt saw a lot of use keeping the gin stands running.

Once formed, each bale would then be wrapped in jute and secured with metal bands, then weighed and stamped with the owner’s name before going on its way to spinning mills, possible even the famous Mississippi Mills in Wesson, Mississippi.

As with all technology, the process of ginning cotton has slowly improved over the years, with research continuing to this day in places such as the Cotton Ginning Research Unit of the USDA’s Cotton Ginning Laboratory in Stoneville, Mississippi. Their goal is to ensure that the cotton “required by the textile industry, and ultimately the consumer” is of the highest possible quality while constantly improving all aspects of the process, from the first handling of the seed cotton to the final disposal of by-products.

The cotton gins of today would appear strange, yet at the same time be recognizable to the 19th Century operators from the Bisland Gin.

Photo at right courtesy of the USDA.

The next time you wear an item of clothing made from cotton, think about all of the work that went into producing the soft fibers that make up the cloth. And remember, the cotton gin is just one small part of the process.

COPYRIGHT © 2011 THE NEW SOUTHERN VIEW | 6/16/15